Why Steel?

Using steel in construction has been around since the late 19th century. Steel as a material was predominantly used for construction of skyscrapers and other typically larger buildings.

The reason steel is popular and sought after in construction is fundamentally because of the strength that the steel yields to the building and the durability it lends, as opposed to using more traditional building materials like wood and bricks. Steel is also considered a “green” product since the material is entirely recyclable.

Using steel however, comes with its own set of challenges, like the material is better at conduction of heat and cold, and this needs to be taken care of during designing.

What is Steel Detailing?

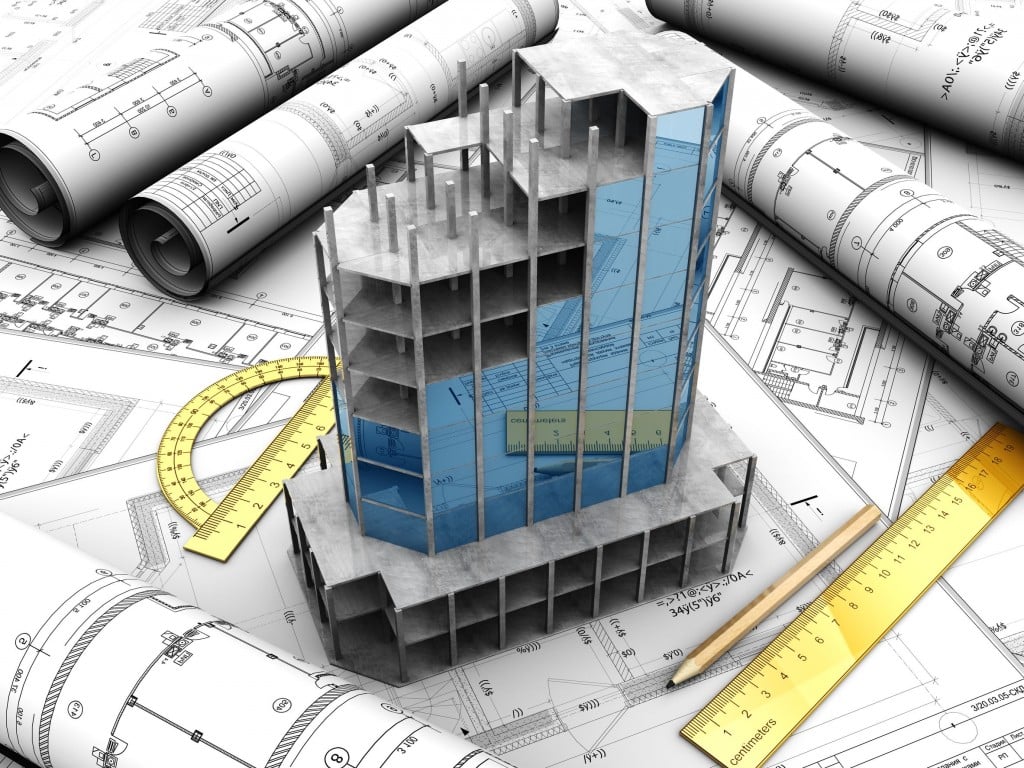

In the process of construction, the Architect first designs the structure based on input from the owners and requirements. These architectural drawings are then used as a reference and Civil drawings are created by the Engineer on the team to calculate the load and requirements based on the Architect’s drawings.

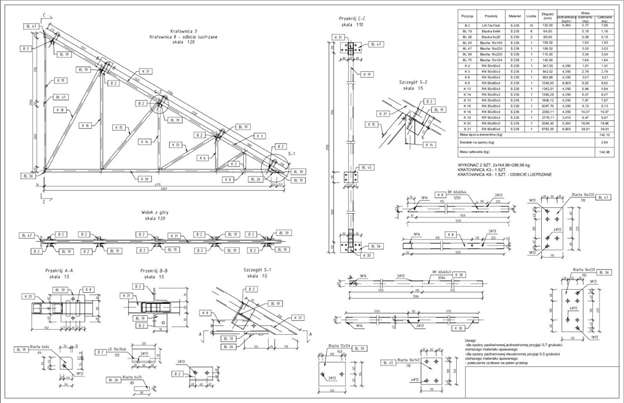

However, these drawings are not sufficient for Steel Fabricators to fabricate or erect steel. This is where steel detailing as a process takes a cornerstone role in the entire process. Steel detailers transform design drawings or design drafts, into “shop” drawings (they are called shop drawings because these drawings are typically used to fabricate the members in the fabricator’s shop) for every single steel component. These shop drawings are required to accurately identify and process specifications and dimensions for fabricating

Once the shop drawings have been sent and verified by the General Contractor (the company that handles the Civil Engineering part of the process) and the Architect, the detailer then produces the next set of drawings known as the erection drawings. These drawings specify the layout of the entire site and also where exactly each fabricated member needs to go in the field.

It is important to note that most detailers also provide their fabricators with Bill of Materials and other files that allow Fabricators to estimate exactly how much material needs to be purchased.

Techniques

Before the rampant overtaking of our workspaces by computers, steel detailing was carried out by using manual drafting methods. As time went by, detailers started using calculators as well as logarithm tables and other mathematical tools.

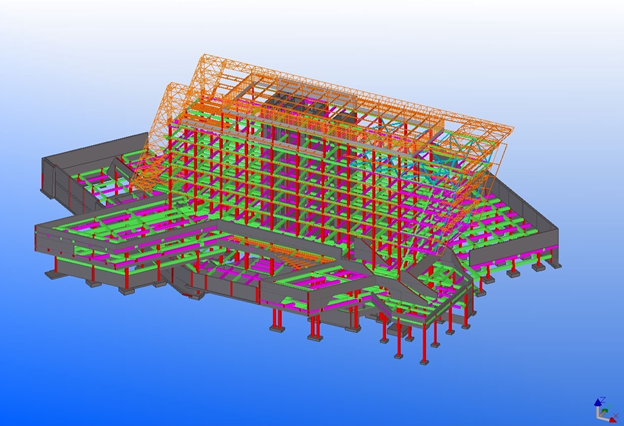

However, in the modern world, industries use CAD or other specific software like TEKLA and SDS/2 for steel detailing. The software makes the process go faster with a very low margin of error. Although the use of software has made steel fabrication easier, the process still requires skill to make sure that it is as accurate as possible. While creating the drawings and getting them approved are very much in the hands of the detailer, the proprietary programs used have added ease and clarity to the digital workflow. Using the program, once the structure has been inputted, shop drawings and material lists can be automatically generated. In some softwares, like TEKLA, the program can even generate all the necessary codes and send them instantaneously to a CNC station so that the fabrication work can commence.

Once the blueprints have been transformed into shop drawings and erection documents, they can be automatically sent over to the workshop as multi-stage workshop instructions. Using this process, a higher degree of work parallelism is incorporated into the work. With numerical codes and material resources streaming off a modern computing network, the system greatly reduces fabricator downtime and keeps the detailing-to-fabrication relationship continually in-sync. Additionally BIM coordination is a lot of the software has allowed 3D coordination between different vendors.

Safety

One of the primary reasons that steel is popular as a building material is because of its strength and durability as discussed. With climate change becoming a more real issue each day, it has become quite difficult to assess and predict with certainty when the next natural calamity or accident can occur. Structural Design companies work keeping in mind the various standard guidelines from organizations like AISC AND CISC to implement designs that are intended to provide maximum stability and protection to the people inside

Benefits of Steel Detailing

The process of steel detailing allows fabricators and erectors to have information rich models and drawings. This helps not just fabricators during the process of fabrication and subsequently erection, but also allows engineers and architects to check the work to ensure accuracy and seamless coordination between the involved teams. Teams working on the material have a better understanding of the final structure based on the 3D visualizations that are created.

Steel detailing therefore is not only essential to ensure smooth and easy fabrication and erection, but also provides a complete overview of the project before actual realization, and also is fundamental to maintaining the safety standards and material utilization.

Leave Comment